At TE, we have been designing and building relays for aerospace and space applications for over 30 years. We routinely use advanced design and manufacturing processes to provide space-qualified products

When NASA’s (National Aeronautics and Space Administration) Curiosity rover made a perfect landing in Gale Crater of Mars, it was 150 million miles from the nearest repairman. Every component has to operate reliably to support the vehicle’s expected operation life of 98 weeks—or one Martian year. Included in the thousands of components on the rover are relays from TE Connectivity. Specifying a relay for space obviously involves finding a compact, lightweight device that meets electrical needs.

Q&A with Karl Kitts, Director of Development Engineering

What do design engineers need to look for when specifying a relay for space?

Temperature extremes are perhaps the first thing that comes to mind, but temperatures are not the only environmental challenges. The ability to operate in a vacuum, to withstand radiation levels, and to handle different atmospheres are important. Launches of space vehicles present mechanical stresses from vibration and acceleration that must also be factored into the selection process.

What about operating in a vacuum?

While relays used in space applications are typically hermetically sealed, seals occasionally leak – or are only good for so many years – a concern on a mission with a long life. Relays that rely on oxide layers, which become unstable in a vacuum, will become unreliable if the seals leak. With that in mind many TE relays used in space environments are manufactured having contacts sealed within a hard vacuum environment and suitable for continuous use in such an environment. Our expertise in materials helps confirm that every part of the relay is ready to perform reliably in harsh conditions – even unexpected ones.

Are there specific requirements in manufacturing for space applications?

Yes. Space relays need to be manufactured in a cleanroom environment. Even minute particle contamination must be avoided during manufacturing to avoid any inconsistency in relay operation. The relay should be expected to operate perfectly every time. For this reason, rigorous cleaning, handling, and storage processes are imposed in order to confirm that space relay materials, components and subassemblies are fully protected throughout the manufacturing process.

How important is environmental stress screening?

Testing of relays for space applications is typically far more involved than testing for terrestrial uses. Tests such as vibration, temperature cycling and thermal shock, and the like are similar except they typically last longer, with more cycles. Such testing may also include an extended temperature range to reflect the temperature extremes of space. The intention is to stress-test the device to a greater degree than required for ground or aerospace needs.

Consult with the relay supplier about the types and extent of testing that may be appropriate for your application. The application environment will differ between a communication satellite and the Mars Rover, for instance. What’s more, the number of operating cycles for the relay may be significantly different depending on its application. For example, a relay used to separate a satellite from the launch vehicle may only need to operate once. A relay that is used in power processing or conditioning, on the other hand, may be required to operate thousands of cycles.

What makes a space relay different from those for terrestrial use?

Relays suited to space applications are available with the same forms and ratings as terrestrial relays. The difference lies in choosing those designed, qualified, manufactured and tested to meet the rigors of a space application.

Need help with your Space project?

At TE, we have been designing and building relays for aerospace and space applications for over 30 years. We routinely use advanced design and manufacturing processes to provide space-qualified products

When NASA’s (National Aeronautics and Space Administration) Curiosity rover made a perfect landing in Gale Crater of Mars, it was 150 million miles from the nearest repairman. Every component has to operate reliably to support the vehicle’s expected operation life of 98 weeks—or one Martian year. Included in the thousands of components on the rover are relays from TE Connectivity. Specifying a relay for space obviously involves finding a compact, lightweight device that meets electrical needs.

Q&A with Karl Kitts, Director of Development Engineering

What do design engineers need to look for when specifying a relay for space?

Temperature extremes are perhaps the first thing that comes to mind, but temperatures are not the only environmental challenges. The ability to operate in a vacuum, to withstand radiation levels, and to handle different atmospheres are important. Launches of space vehicles present mechanical stresses from vibration and acceleration that must also be factored into the selection process.

What about operating in a vacuum?

While relays used in space applications are typically hermetically sealed, seals occasionally leak – or are only good for so many years – a concern on a mission with a long life. Relays that rely on oxide layers, which become unstable in a vacuum, will become unreliable if the seals leak. With that in mind many TE relays used in space environments are manufactured having contacts sealed within a hard vacuum environment and suitable for continuous use in such an environment. Our expertise in materials helps confirm that every part of the relay is ready to perform reliably in harsh conditions – even unexpected ones.

Are there specific requirements in manufacturing for space applications?

Yes. Space relays need to be manufactured in a cleanroom environment. Even minute particle contamination must be avoided during manufacturing to avoid any inconsistency in relay operation. The relay should be expected to operate perfectly every time. For this reason, rigorous cleaning, handling, and storage processes are imposed in order to confirm that space relay materials, components and subassemblies are fully protected throughout the manufacturing process.

How important is environmental stress screening?

Testing of relays for space applications is typically far more involved than testing for terrestrial uses. Tests such as vibration, temperature cycling and thermal shock, and the like are similar except they typically last longer, with more cycles. Such testing may also include an extended temperature range to reflect the temperature extremes of space. The intention is to stress-test the device to a greater degree than required for ground or aerospace needs.

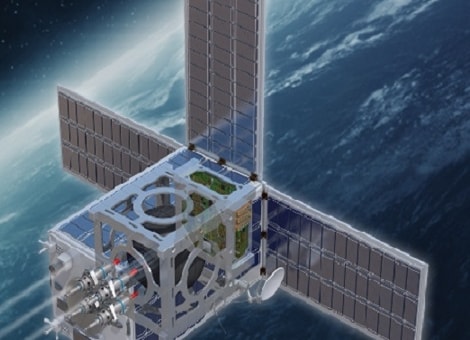

Consult with the relay supplier about the types and extent of testing that may be appropriate for your application. The application environment will differ between a communication satellite and the Mars Rover, for instance. What’s more, the number of operating cycles for the relay may be significantly different depending on its application. For example, a relay used to separate a satellite from the launch vehicle may only need to operate once. A relay that is used in power processing or conditioning, on the other hand, may be required to operate thousands of cycles.

What makes a space relay different from those for terrestrial use?

Relays suited to space applications are available with the same forms and ratings as terrestrial relays. The difference lies in choosing those designed, qualified, manufactured and tested to meet the rigors of a space application.