Engineered for reliability

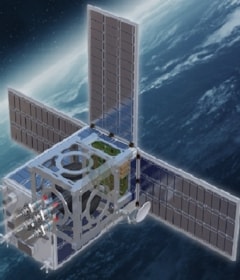

Look to DEUTSCH hermetic connectors from TE Connectivity (TE) for reliable, air- and gas-tight connections. For applications ranging from submarines and satellites to aircraft and offshore exploration and production, DEUTSCH hermetic connectors are an excellent choice for harsh application environments. We have four decades of experience in producing glass-to-metal seals for applications where temperature, pressure and environmental considerations render standard connectors unusable.

We design and manufacture all the components in our hermetic connectors. We start with high-grade materials — from stainless steel bar stock or exotic metals like titanium for shells, high-grade silica and binders for the glass, and a range of special alloys for contacts, and elastomers carefully matched to the application. An important consideration in material selection is the ability to withstand the high temperatures of the sealing process. All connectors are fully leak tested to ensure the integrity of the hermetic seal.

Hermetic connectors are used to separate an inert atmosphere or vacuum on one side from wide-ranging high-pressure, hightemperature, or corrosive conditions on the other. They are also used to maintain a pressure differential between the two sections. In short, DEUTSCH hermetic connectors are designed to help provide a continuously gas-tight seal while withstanding: • High pressures • Extreme temperatures • High vibration

TE's DEUTSCH hermetic connectors are produced using both matched seals and compression seals. In a matched seal, the metal and glass have similar coefficients of thermal expansion (CTE). This reduces stress on the glass from thermal expansion and contraction. In a compression seal, the metal has a higher CTE than the glass. During the firing process to manufacture the connector, the metal expands more than the glass. As the glass and metal then cool, the metal contracts back onto the glass to form an extremely robust bond. Compression seals are used high-pressure applications.