Trend Insight

Commercial-off-the-Shelf Solutions for LEO Satellites

The shift from one-off, specialized GEO satellites to mass-produced constellations of LEO satellites puts pressure on designers and manufacturers to cut production costs and timelines. Commercial-off-the-shelf (COTS) and COTS+ solutions allow satellite manufacturers to get readily available, reliable components from a trusted source.

Evolution of Satellite Manufacturing from GEO to LEO

Until relatively recently, most satellites have been designed and built for Geosynchronous Equatorial Orbit (GEO) or geostationary orbit. These satellites are positioned approximately 36,000 km (22,400 miles) above the equator and rotate at the same speed and in the same direction as the Earth. This fixed positioning ensures that satellite transmission remains consistent and focused on a particular region of the Earth. GEO satellites weigh one to five tons, cost between $100 million and $400 million, and take three to five years to design and build. They are typically built for a specific purpose, which requires custom solutions that can withstand the extreme environmental conditions of space throughout the satellite’s 25- to 30-year functional life cycle. Due to the intensive time and cost factors, only one to three GEO satellites are launched annually.

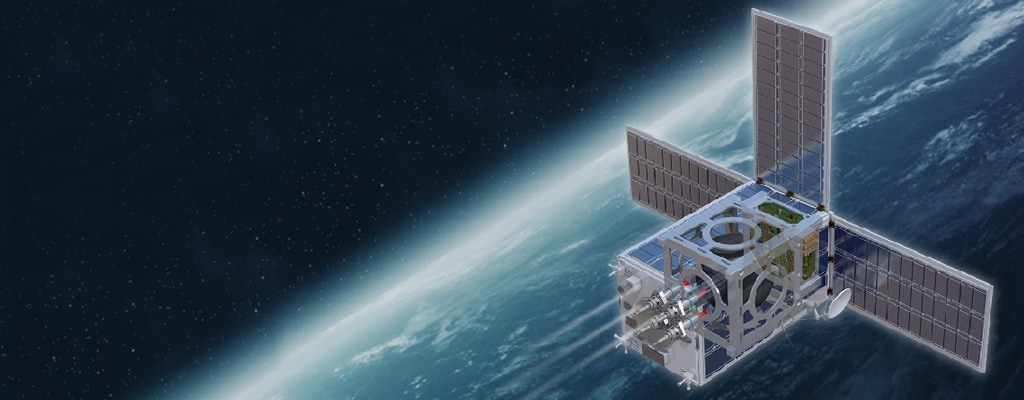

Today, most satellite manufacturing is focused on Low Earth Orbit (LEO) satellites, which are generally situated 160 to 1,900 km (100 to 1,200 miles) from Earth. LEO satellites are not fixed to one point and orbit the Earth continuously. A constellation of hundreds of LEO satellites may be required to completely cover the globe.

The range of LEO satellites includes small devices, 100 kg (220 lbs), that are quickly assembled using 10-cm (4-in) cubes that contain consumer-grade computer hardware to larger satellites that are purpose-built using mostly COTS components. Larger, more common LEO satellites weigh between 100 and 1,000 kg (220-2,200 lbs). Their average cost is $500,000, and they can be produced—from design to finished satellite—in about 18 months. This much more agile production process and timeline, coupled with a lower launch cost compared to GEO satellites, is fueling a boom in LEO satellites, with launches on a nearly daily basis.

Growth of LEO Satellite Applications

LEO satellites deliver high bandwidth with low latency, which makes them ideal for sending signals to and from the Earth’s surface. As a result, there is an ever-increasing number of applications for LEO satellites. Currently, they are primarily used to enable global connectivity and to observe various phenomena on Earth:

Global Connectivity

- Delivering broadband internet connectivity to people in remote locations without access to Earth-based telecommunications infrastructure. Enabling internet connectivity on airplanes for in-flight entertainment and other services for passengers and crews.

- Enabling the Internet of Things (IoT) by interconnecting “smart” devices, appliances, and equipment for residential, commercial, industrial, and military use.

Observation and Data Collection

- Monitoring environmental conditions including current weather readings, the Earth’s surface temperatures, wave heights, humidity levels, wind speeds, or pollen counts, and using that data to track the effects of environmental disasters.

- Improving agricultural production through access to low-cost satellite data to help farmers determine the best crops to plant and the ideal time to plant them, as well as to provide live updates as crops grow.

- Optimizing transportation on land, at sea, and in the air by tracking trucks, ships, planes, and other vehicles to estimate arrival times and help identify more efficient routes.

LEO satellites are also well-suited for the fast-approaching space-to-space economy, a strategy of transmitting data from a satellite in space to another object in space, instead of transmitting to an object on Earth. This will be critical in supporting orbit transfers, fuel stations, data centers, and more.

As the list of communications, imaging, and LEO satellite applications grows, so does the need for broader coverage through a larger network of satellites at low Earth orbit. Designers and manufacturers will need to rely on COTS solutions to keep up with the demand for more, less expensive LEO satellites.

Improve Efficiency, Reduce Costs with

COTS Components

COTS components are ready-made products that can be used in the manufacture or assembly of a finished product. COTS+ refers to off-the-shelf items that have been slightly modified for a specific application or to withstand the harsh environment of space. COTS+ components receive additional testing and/or physical upgrades to meet the demands of LEO. These items have been validated to work in a space environment.

However, designers and manufacturers can’t compromise performance or durability as they search for lower-cost solutions. LEO satellites must still be rugged enough to withstand extreme temperature changes and survive high vibrations, particularly at launch. This is why most LEO satellites that include COTS and COTS+ components also require components built to the more rigorous VITA and SOSA space-grade standards for mission-critical elements.

Demand Drivers for

COTS Components

Quantity of Satellites

- Constellations of tens or hundreds of LEO satellites collect large amounts of data and provide dependable services to customers around the world. Several leading satellite internet service providers, for example, produce and launch dozens of LEO satellites per week, with plans to ultimately have tens of thousands of satellites in orbit.

Short Life Spans

- Each LEO satellite has only a three- to five-year life span. Designers don’t have to worry about cosmic solar radiation, atomic oxygen erosion, and other factors that can limit the life cycle of hardware in a very hostile deep-space environment. So the need for more rugged, space-grade hardware becomes less critical.

Continuous Improvements

- LEO satellites are designed to evolve, with gradual software updates and incremental changes in the technology to improve existing functions or add new capabilities. New satellites can be built using the latest technology that meets today’s needs and anticipates tomorrow’s technical advances.

Integration with GEO Satellites

- For situations when both low latency and high processing power are required—such as streaming video services—LEO satellites can work in tandem with existing GEO satellites to deliver the best connectivity.

Industry Market Trends

- The number of mergers and partnerships among satellite companies is increasing as the industry grows and matures. Integrating one company’s product with another is more seamless when both products use common, off-the-shelf components.

Affordability and Customer Satisfaction

- Using COTS parts helps speed assembly of new satellites and reduce production costs. As a result, internet- or phone-service providers who rely on LEO satellites have the opportunity to make their services available to more people at lower prices.

Off-the-Shelf Solutions for LEO Satellite Applications

TE Connectivity (TE) offers a broad space-ready portfolio of wire, cable, relays, contactors, sensors, and connectors that are ideally suited to the rigors of LEO satellite applications, including the following off-the-shelf solutions:

- STRADA Whisper High-Speed Backplane Connectors were designed for high-performing, high-bandwidth systems. Their revolutionary design transfers data up to 112 Gbps to allow for efficient future system upgrades without costly backplane or midplane redesigns.

- Micro-D and D-Subminiature Backshells meet the functional, material, and performance demands for spacecraft applications where quality and affordability count.

- Fiber Optic Assemblies reduce size, weight, and power (SWaP), as well as align with high density and electromagnetic interference (EMI) resistance requirements to fully support high-speed communication, data, and payload system architecture.

- Active Optical Cable Assemblies offer greater cable flexibility and longer reach, as compared to both traditional passive copper solutions and emerging active copper (ACC/AEC) solutions. They support high-performance computing, data center, and networking interconnect applications.

- 369 Small Form Factor Connectors provide a range of high reliability, lightweight, compact, and cost-efficient connectors suited to harsh environment applications.

Beyond products, TE engineers have the experience and expertise to help you find the ideal COTS components or COTS+ solutions for your next LEO satellite design.

Connect with TE

Contact TE to discuss your next connectivity project with one of our engineers.

Key Takeaways

- The evolution from one-off, specialized GEO satellites to mass-produced constellations of LEO satellites leads to a greater need for commercial-off-the-shelf (COTS) and COTS+ components that help cut production costs and shorten timelines.

- LEO satellites, located 160 to 1,900 km (100 to 1,200 miles) from Earth, deliver high bandwidth with low latency to enable global connectivity and to observe various phenomena on Earth.

- Satellite designers and manufacturers increasingly rely on COTS parts to keep up with the demand for less expensive LEO satellites.

- TE Connectivity (TE) offers a broad portfolio of readily available, reliable off-the-shelf solutions that are ideally suited to the rigors of LEO satellite applications.